Introduction: Why GP Pipes Matter for Modern Projects

For engineers, contractors, purchase managers, and project planners, choosing the correct steel pipe is a technical decision with direct impact on safety, performance, and lifecycle cost. Yet many teams still treat GP Pipes as a commodity item instead of a carefully engineered material choice.

Asian Steels, part of the Asian Group of Companies based in Ahmedabad, Gujarat, supplies MS Pipes, GP Pipes, and GI Pipes to critical projects across India. As a manufacturer of steel pipes in India, the company works closely with industrial clients to ensure that the right pipe type is selected for each application.

This guide explains in clear, technical language what GP Pipe is, how it is manufactured, how it compares to MS and GI alternatives, and where it should be specified. By the end, you will have a practical framework for deciding when GP Pipes are the correct solution for construction, furniture, scaffolding, pipe fencing, industrial frameworks, and engineering applications.

What Is GP Pipe? A Technical Definition

India’s industrial growth has rapidly increased the demand for reliable, standardized steel pipes. GP Pipes have become a key element in this ecosystem because they match typical Indian project conditions: variable humidity, partially sheltered structures, and value-conscious budgets.

As a manufacturer of steel pipes in India, Asian Steels focuses its GP Pipe portfolio on real-world Indian environments rather than theoretical lab conditions. This means considering:

- Local humidity and temperature cycles

- Dust, pollution, and industrial atmosphere

- Common fabrication practices in Indian workshops

- Typical maintenance intervals on construction and industrial sites

For buyers, working with a manufacturer of steel pipe that understands these conditions helps avoid over-specification (unnecessary cost) or under-specification (premature failures).

GP Pipes in the Indian Industrial Context

India’s industrial growth has rapidly increased the demand for reliable, standardized steel pipes. GP Pipes have become a key element in this ecosystem because they match typical Indian project conditions: variable humidity, partially sheltered structures, and value-conscious budgets.

As a manufacturer of steel pipes in India, Asian Steels focuses its GP Pipe portfolio on real-world Indian environments rather than theoretical lab conditions. This means considering:

- Local humidity and temperature cycles

- Dust, pollution, and industrial atmosphere

- Common fabrication practices in Indian workshops

- Typical maintenance intervals on construction and industrial sites

For buyers, working with a manufacturer of steel pipe that understands these conditions helps avoid over-specification (unnecessary cost) or under-specification (premature failures).

How GP Pipes Are Manufactured: Step-by-Step

1. Coil Selection and Slitting

The process begins with mild steel coils that meet defined chemical and mechanical parameters. Control over carbon content, yield strength, and elongation is essential.

Coils are slit into strips of precise width for each pipe size. A responsible manufacturer of steel pipe ensures slit edges are clean and burr-free to support sound welding and straightness.

2. Forming and High-Frequency Welding

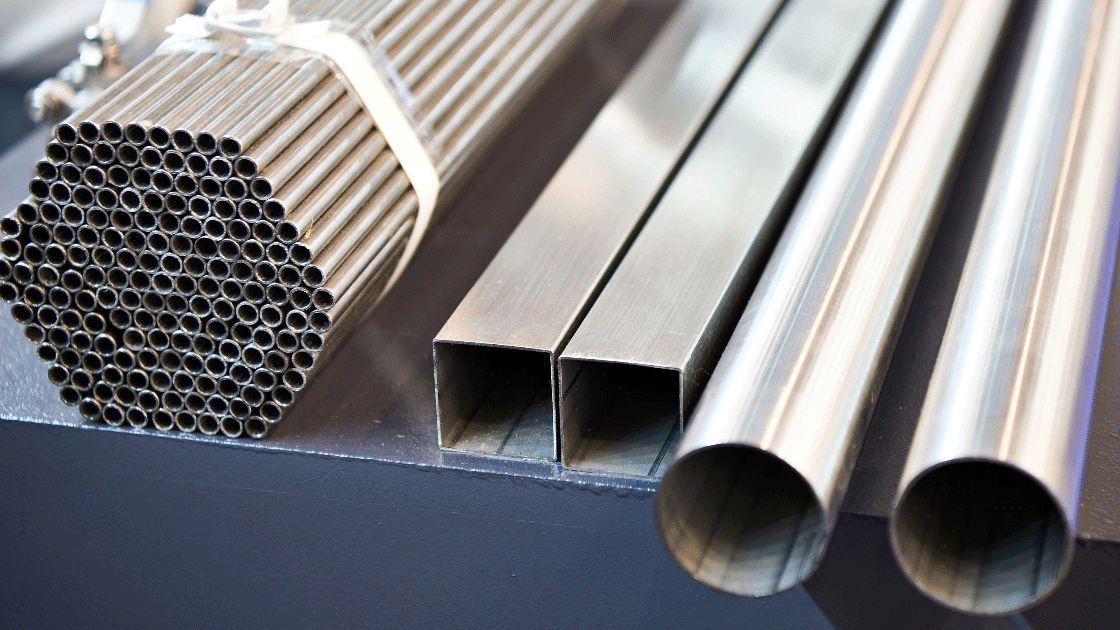

The strips are progressively formed into a circular or square profile using roll-forming mills. Once the edges meet, high-frequency welding creates a continuous longitudinal seam.

At this stage, the product resembles MS Pipes such as MS ERW Black Pipe and MS Square/Rectangular Steel Pipes, which can either be supplied as MS or further processed into GP Pipes.

3. Sizing, Straightening, and Cutting

The tube passes through sizing rolls to bring it to final dimensions. Straightening machines ensure linearity, and pipes are cut to length using cold saws or flying cutters.

4. Galvanization and Surface Conditioning

The steel tubes are galvanized with zinc. The coating is optimized for indoor and under-roof environments and provides good paint adhesion.

Related products: MS ERW GI Pipe, GI Square and Rectangular Steel Pipes, GP/GC Coil Steel Sheets.

GP Pipes vs MS Pipes vs GI Pipes

GP Pipes vs MS Pipes

MS Pipes provide structural capability but no inherent corrosion protection. GP Pipes include a zinc coating for improved resistance to rust. For indoor frameworks and furniture structures, GP Pipes are often the better choice.

GP Pipes vs GI Pipes

GI Pipes have heavier zinc coatings and are designed for high-exposure conditions. GP Pipes are better for precision structural use with clean aesthetics and tight dimensional control.

Key GP Pipe products: GP Round Steel Pipe and GP Square & Rectangular Steel Pipes.

Performance Characteristics

- Mechanical Strength: Suitable for light to medium loads.

- Corrosion Resistance: Zinc coating delays rust formation.

- Dimensional Accuracy: Tight tolerances for visible and fabricated applications.

Major Applications

Construction

Used in railings, staircase guards, canopy supports, and more. A steel pipe manufacturer in Gujarat like Asian Steels can supply cut-to-length GP Pipes for jobsite efficiency.

Furniture

GP Pipes enable modular and durable furniture, racking, and shelving systems. Also used with CRCA Coil Steel Sheets for complementary fabrication.

Scaffolding

Provides strength, corrosion resistance, and workability for scaffolding systems.

Pipe Fencing

Ideal for factory perimeters and institutional fencing in semi-exposed conditions.

Industrial Frameworks

Supports cable trays, light mechanical frames, and walkways. Refer to: Applications.

When to Use GP Pipes

- Semi-exposed or indoor settings with moderate humidity

- Furniture, partitions, and painted visible structures

- Modular construction and cost-sensitive projects

- Where MS is not durable enough, and GI is over-specified

Why Choose Asian Steels

- Complete range of MS, GP, and GI pipes

- In-house galvanizing and quality control

- Regional delivery across India

- Known as India’s trusted steel pipe supplier

Explore: Our Facilities | Quality Standards

Contact Us

Contact us for a quote and technical consultation on your next requirement.

Explore Our Products

Browse full product range: View our product range

Become a Dealer

Interested in partnering with a reputed steel pipe manufacturer? Become a dealer with Asian Steels.

Get in Touch

For application support, case studies, and project guidance, Explore our applications.